Some progress before all of the rain came.I just got all of the long straight sections and hitch cleaned up.

Found out why this didn't rust so bad over the years, it's heavily coated with lead based paint. Had to setup the air compressor, grind in only one direction and trap all of the white powered lead paint into a collector. Else, it would of been super easy with the power washer to strip it all.

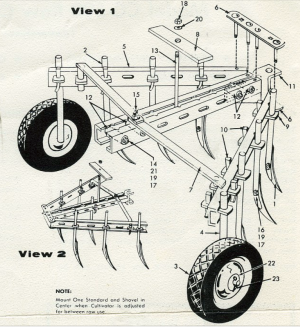

It's everything on the black cart in the photo.

The difficult part is stripping the round shaft like parts from the paint. All the parts in the box.

I'll do 2-coats of primer and then a nice finish coat of the Club Cadet white it once had without the lead.

The carriage bolts I'll price at Menards or the H-D. Too pricey at ACE.

I like the original square nut on the back top. It came off easy after a soak in Deep Creep. Finding an exact replacement will be a chore.

A bit of sanding and cleaning. Nothing like 40+ years of tarnish and grime. 4 on the right are the best I could do.

Cleaned a bit, and painted some.